E36 Fan & Shroud Procedure

The following information is provided for reference purposes only and should be used at your own risk

In no event shall Beisan Systems, LLC or its members be liable for incidental, consequential, or special loss or damages of any kind however caused.

Fan & shroud removal

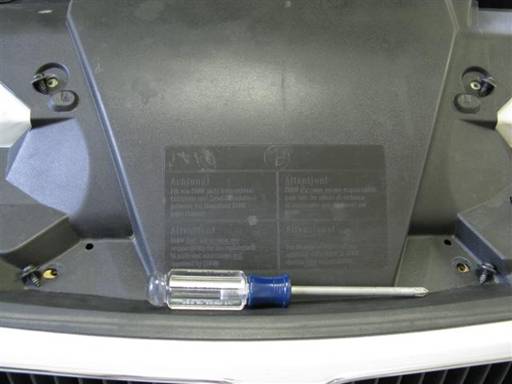

Remove 4 screws from air duct at top of car frame and radiator (Philips).

Remove two rivets at each end of air duct.

Remove center screw (medium Philips).

Pry out rivet base (tack lifter).

Note: Press in on screw while threading out. Change to a larger Philips head if necessary. If center screw does not unthread, pry out rivet and attempt to break (tack lifter). Replace rivet.

Pull rear air duct out of alternator air duct and bend down and raise above retaining bridge.

Lift up air duct from rear and remove from car frame.

Unscrew overflow hose clamp at radiator right top (Philips).

Pry hose off radiator overflow neck (flathead).

Remove hose clamp from hose to keep from loosing.

Note: If overflow hose clamp original, pry open clamp to remove (small flathead) and replaced with adjustable hose clamp.

Remove rivet at each top corner of fan shroud. Pry out rivet center pin (tack lifter), then fully pry out rivet from base (tack lifter).

Insert hose onto radiator overflow neck and clamp opposite hose end (vacuum hose, clamp)

Note: This will prevent coolant leak when removing fan shroud.

Remove fan, belt static friction method.

Remove fan / fan clutch from water pump shaft.

Place open wrench on fan clutch nut (32mm combo wrench). Place wrench forward on nut to avoid hitting vanos body and radiator hose clamps. Strongly strike wrench side at top with heavy hammer to break nut seize (sledge hammer); left hand thread.

Note: Nut is left hand thread, thus unscrew by hitting wrench top from left to right (car front orientation). Serpentine belt static friction on water pump pulley facilitates large enough opposing force to break nut seize. It is important to use a heavy hammer to produce a high instantaneous jerk. Several attempts will be needed before nut seize breaks. Rotate open wrench to reposition for better access.

If belt static friction method is not successful, attempt pulley holding tool method.

Remove fan, pulley holding tool method.

Remove fan / fan clutch from water pump shaft.

Position water pump pulley for holding tool access. Water pump pulley has 2 (adjacent) pairs of mounting bolts. Position one of the bolt pairs with left bolt at just to right of top center (picture) (32mm combo wrench).

Install water pump pulley holding tool onto pulley bolts. Position holding tool at right, and place tool indent curve against fan clutch nut. Mount tool end hole onto pulley bottom left bolt, and tool second hole onto pulley right bolt. Reposition fan clutch nut for better holding tool access (picture).

Place open wrench on fan clutch nut (32mm combo wrench). Counter hold holding tool and break clutch nut seize (32mm combo wrench); left hand thread.

Note: Nut is left hand thread, thus unscrew by turning wrench from left to right (car front orientation).

If fan clutch nut seize difficult to break, apply lubricant to nut/threads contact surfaces (spray lubricant).

Once nut seize is broken, remove tools and spin fan blades to unscrew nut; left hand thread.

When nut is close to shaft end, turn fan slowly while continuously holding fan blades. This will keep fan from falling and damaging radiator fins when fully disconnected.

Lift fan shroud up while maneuvering fan / fan clutch out of fan shroud and engine bay.

Remove coolant level sensor electrical connector at bottom of coolant reservoir.

Press down electrical connector end tab and wiggle off connector.

Remove coolant hose from fan shroud inner bottom brackets.

Lift up fan shroud and pull away from radiator to facilitate better access.

Pull overflow hose right end out of shroud access hole and clamp end (clamp).

Note: This will prevent coolant leak when removing fan shroud.

Partially remove fan shroud.

Lift up shroud and pull shroud lower coolant hose out of shroud from shroud right side.

Tilt shroud right side up to facilitate space for shroud left side lower tab to clear and lift above radiator lower hose.

Fully remove fan shroud.

Continue to pull shroud coolant hose out of shroud while pulling shroud up and out.

Rotate shroud and lay on top of right side engine components. Pull out coolant hose further as needed.

Fan & shroud installation

Partially install fan shroud.

Rotate fan shroud and lower into mounting slot adjacent to radiator. Pull shroud coolant hose into shroud to facilitate positioning.

Lower shroud left side and raise shroud right side to allow shroud left lower tab to clear and lower below radiator lower hose.

Install fan shroud.

Continue to pull coolant hose into shroud and lower shroud into position.

Remove clamp from radiator overflow hose and feed hose end through shroud access hole.

Mount overflow hose into shroud bracket along shroud top.

Mount coolant hose into fan shroud lower brackets. Pull coolant hose in/out of shroud to facilitate proper fit.

Take note of coolant hose fit at shroud bottom right corner. Adjust coolant hose to fit snug against shroud.

Install coolant level sensor electrical connector at bottom of coolant reservoir. Press in connector until it snaps in place.

Insert fan/clutch in fan shroud. Lift shroud up and forward while maneuvering fan/clutch into shroud.

Note: Fan is oriented with clutch nut to car rear.

Align shroud by pulling up, forward, and dropping down into position.

Mount fan/clutch onto water pump shaft.

Lift fan and mate (hang) fan clutch nut onto water pump shaft. Rotate fan to find best nut thread to shaft thread mate. At optimal fit, fan will hang on shaft without threading (picture).

With fan hanging independently on shaft, slowly turn fan blades to thread nut onto shaft; left hand thread. Fully thread nut onto shaft.

Place open wrench on fan clutch nut (32mm combo wrench) and lightly hit wrench top with heavy hammer, one time; left hand thread (sledge hammer).

Note: Serpentine belt static friction on water pump pulley facilitates large enough opposing force to tighten clutch nut. Fan opposing spin also tightens fan clutch nut.

Fully install fan shroud. Lift fan shroud up, pull forward, and drop down to mount into side and top radiator frame slots.

Note: Fan shroud should insert fully and align with radiator frame.

Verify shroud right side tabs inserted into radiator slots.

Verify shroud left side tabs inserted into radiator slots.

Lower tab can be verified by attempting to pull off shroud from under car.

Verify shroud upper tab fits over radiator rail.

Overflow hose mounting in shroud can be verified from rear side of radiator.

Remove leak prevention hose and clamp from radiator overflow neck.

Install rivet at top right corner of fan shroud. Pry rivet center pin out, fully insert rivet base into shroud, then press in rivet center pin.

Note: If pin insertion is difficult, use tool to apply stronger force (flathead) and shift shroud laterally to facilitate better alignment.

Remove retaining plastic clip at expansion tank bleed screw. Press in at both wings and lift up clip (2 flatheads).

Note: Unscrew/re-screw expansion tank cap as needed to remove clip.

Install rivet at top left corner of fan shroud. Pry rivet center pin out, fully insert rivet base into shroud, then press in rivet center pin.

Note: If pin insertion is difficult, use tool to apply stronger force (flathead) and shift shroud laterally to facilitate better alignment.

Install retaining plastic clip at expansion tank bleed screw. Push down clip until it snaps in.

Unscrew/re-screw expansion tank cap as needed to facilitate access.

Insert overflow hose clamp onto overflow hose with clamp bolt head at top and facing right (picture). Mount overflow hose onto radiator overflow neck. Position hose clamp onto radiator overflow neck and tighten clamp (Philips).

Install air duct onto car frame.

Insert air duct into frame hole and lay on frame.

Bend rear air duct down and under retaining bridge.

Insert rear air duct into alternator air duct.

Align air duct on car frame.

Install 4 screws to mount air duct. Do not fully tighten.

Install 2 rivets at each end of air duct. Fully insert rivet base, then screw in center screw (Philips).

Note: Press in on screw while threading.

Fully tighten 4 mounting screws and 2 end rivet center screws (Philips).

© 2024 Beisan Systems LLC